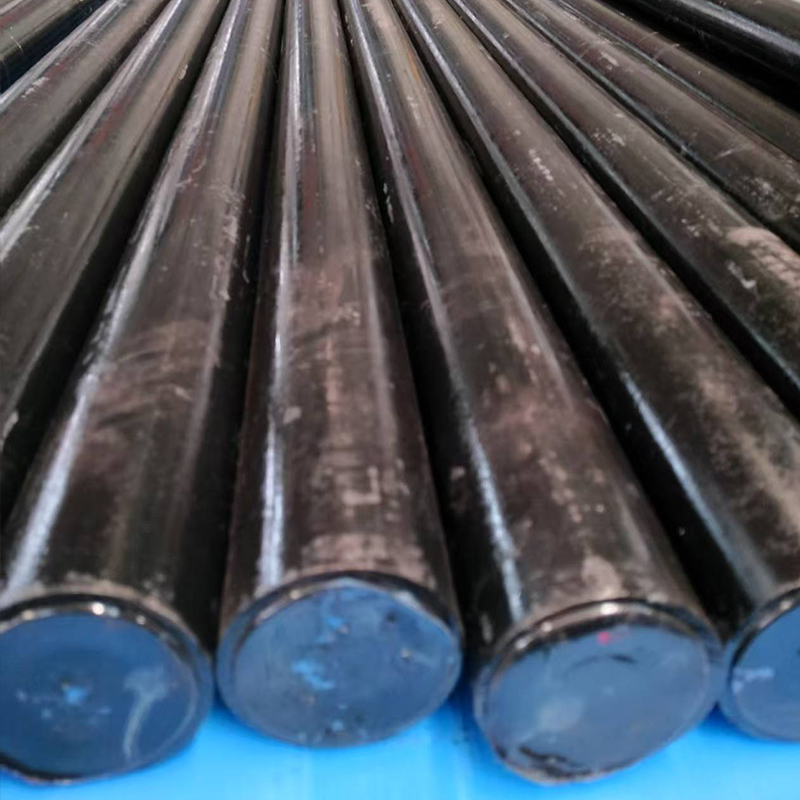

High Pressure Boiler Internal Thread Seamless Tube Alloy Steel Material High Temp Resistance for Power Plant Boilers

OEM/ODM Custom Pipe Fittings

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

Lead Time:

| Quantity (pieces) | 1 – 100 | 101 – 1000 | > 1000 |

| Lead time (days) | 15 | 20 | To be negotiated |

Customized packaging(Min. order 10 pieces)

Graphic customization(Min. order 10 pieces

For actual requirements, please contact customer service.

Description

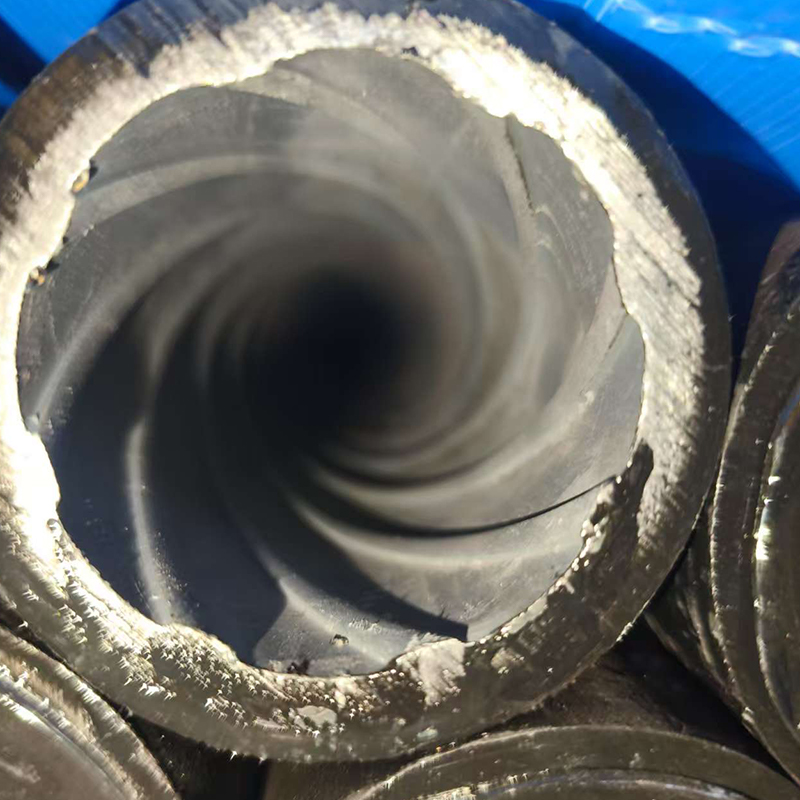

- Thread-Enhanced Heat Transfer: The inner wall of the tube adopts a precise spiral thread design, which significantly increases the heat transfer surface area (by more than 60% compared with smooth seamless tubes). At the same time, it disrupts the flow boundary layer of the medium inside the tube, forming intense turbulence. The heat transfer coefficient is increased by 45%-70%, enabling rapid transfer of high-temperature thermal energy in high-pressure boilers, reducing the risk of local overheating, and ensuring stable boiler thermal efficiency.

- Seamless Structure for Pressure Resistance: Adopting an integrated seamless rolling process, the tube body has no welded joints, and the wall thickness uniformity is controlled within ±3%. It can withstand long-term high-pressure working conditions of 10MPa-35MPa, and its compressive strength is more than 50% higher than that of ordinary seamed tubes. It can stably cope with pressure impacts caused by boiler start-stop and load fluctuations, eliminating the hidden danger of tube leakage.

- Excellent Anti-Scaling Performance: The internal thread structure causes the medium to generate a spiral scouring effect when flowing inside the tube, reducing the adhesion area of scale on the tube wall. Meanwhile, the roughness of the inner tube wall is controlled at Ra≤0.6μm, reducing the adhesion force of scale. The scaling rate is 40%-60% lower than that of smooth tubes, avoiding the decline in heat transfer efficiency and tube corrosion caused by scaling.

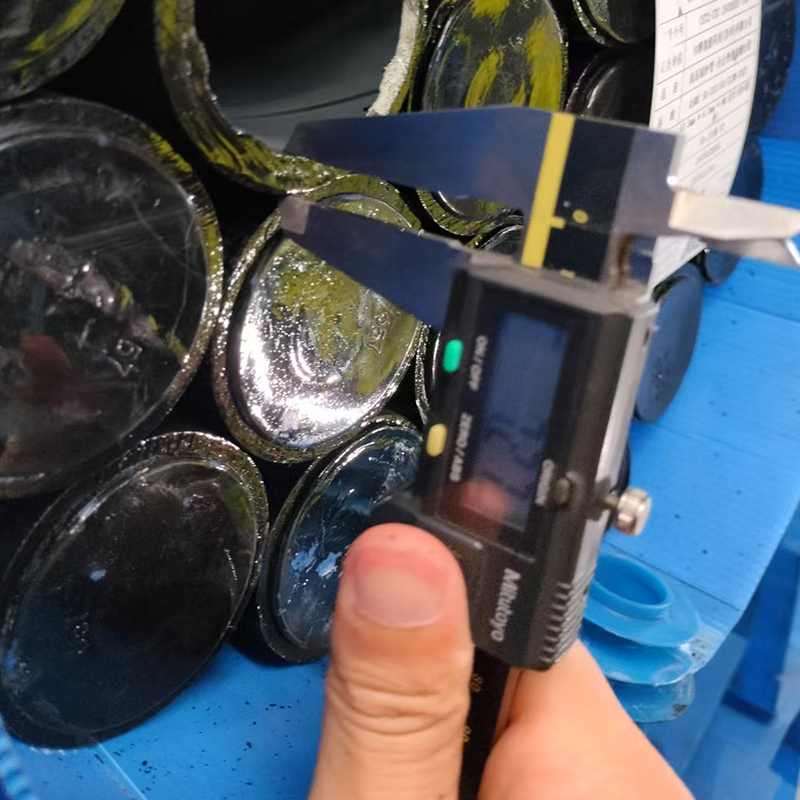

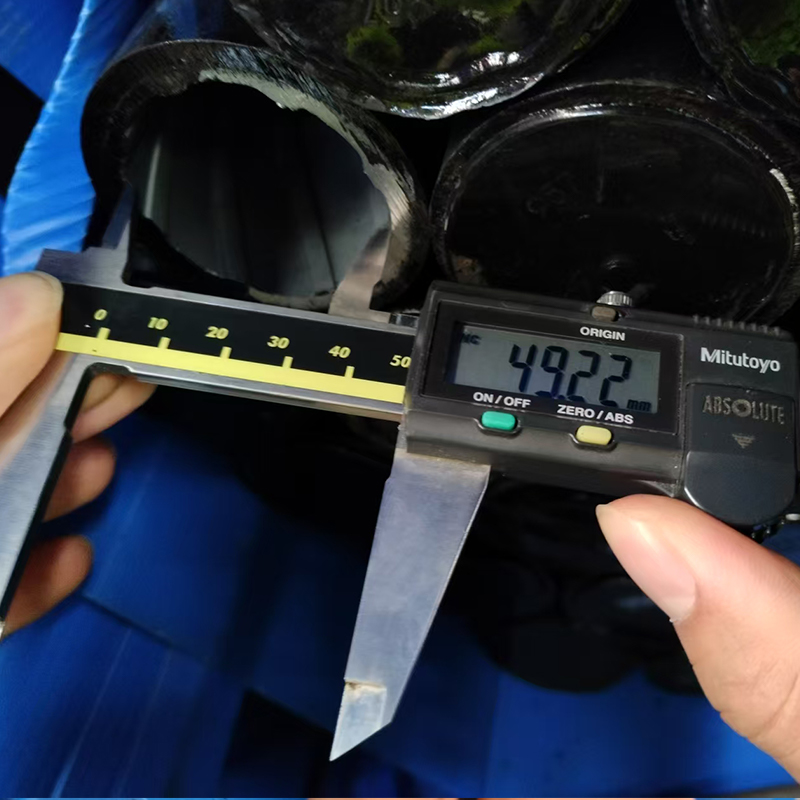

- Precise Dimensional Accuracy: Through multiple precision sizing and thread processing technologies, the pipe diameter tolerance is ≤±0.15mm, the thread profile and pitch deviation are ≤0.05mm, and the tube straightness reaches ≤1.2mm per meter. This ensures precise connection with boiler superheaters, reheaters and other components, reducing installation gaps and lowering medium flow resistance.

- High Efficiency and Energy-Saving Characteristics: Relying on the advantage of thread-enhanced heat transfer, under the premise of meeting the thermal demand of high-pressure boilers, the number of boiler heat exchange tubes can be reduced (saving 20%-30% of pipe material consumption), and the overall volume and weight of the boiler can be reduced. At the same time, it reduces heat loss, helping enterprises save 15%-25% of fuel consumption annually, which is in line with industrial energy conservation and consumption reduction policies.

- Full-Working-Condition Adaptability: Customization of tube length (4m-20m), pipe diameter (16mm-133mm) and thread parameters (tooth height, pitch) is supported according to the type of high-pressure boiler (power station boiler, industrial steam boiler, waste heat boiler, etc.). It is compatible with boiler systems using different heat sources such as fuel oil, natural gas and coal, without the need to modify the original heat exchange structure of the boiler, and its adaptability is far superior to that of ordinary smooth seamless tubes.

- Strict Quality Assurance: Each pipe undergoes four rounds of quality inspection: “non-destructive testing (UT+PT inspection) + high-pressure hydrostatic test (1.8 times the rated pressure) + thread accuracy inspection + chemical composition analysis”, with a 100% qualification rate. It also complies with domestic and international standards such as GB 5310 “Seamless Steel Tubes for High-Pressure Boilers” and ASTM A213, and is accompanied by a complete quality traceability report to prevent unqualified products from entering the market.

- Low Operation and Maintenance Cost: It has excellent anti-scaling and anti-corrosion performance, and can achieve 4-6 years of maintenance-free operation under normal working conditions, which is more than 30% longer than the maintenance cycle of ordinary smooth seamless tubes. At the same time, the thread structure facilitates later pipe cleaning, shortening the maintenance time by 50%, reducing boiler downtime and improving the continuity of enterprise production.

- Special Boiler Steel Materials: Mainstream high-pressure boiler special steels such as 15CrMoG, 12Cr1MoVG and SA-213 T91 are adopted. Among them, 15CrMoG contains chromium and molybdenum alloys, with a high-temperature strength of more than 480MPa, and can work for a long time below 550℃; 12Cr1MoVG is added with vanadium, which improves the high-temperature oxidation resistance by 35% and is suitable for working conditions below 600℃; SA-213 T91 contains 9% chromium and 1% molybdenum, with excellent high-temperature creep strength, and can withstand high-pressure and high-temperature environments above 650℃.

- Strong High-Temperature Stability: Through high-temperature normalizing + tempering + quenching and tempering treatment, the metallographic structure of the pipe is uniform and stable. Under the long-term working temperature of 450-650℃, the thermal expansion coefficient is controlled at 10.5×10⁻⁶/℃-12×10⁻⁶/℃, avoiding thermal stress cracks caused by sudden temperature changes. At the same time, the high-temperature long-term strength reaches more than 200MPa (550℃/100,000 hours), ensuring that the tube structure does not undergo plastic deformation during long-term use.

- Excellent Corrosion Resistance: The chromium element in the material forms a dense Cr₂O₃ oxide film, which can resist the erosion of corrosive media such as high-temperature water vapor, dissolved oxygen and chloride ions in high-pressure boilers. After passivation treatment, the pitting corrosion resistance of the pipe is improved by 50%. In the boiler feed water environment with a pH value of 9-11, the corrosion rate is ≤0.05mm/year, extending the service life of the pipe.

- Power Station Boiler Field: It is suitable for the superheater and reheater systems of large thermal power plants and nuclear power plant auxiliary boilers. It undertakes the functions of heating and transporting high-temperature and high-pressure steam. Through enhanced heat transfer, it reduces the temperature difference of the superheater tube wall, avoids steam temperature fluctuations, ensures the stable output power of generator sets, and meets the power grid load demand.

- Industrial Steam Boiler Field: Used in high-pressure industrial steam boilers in iron and steel, chemical, oil refining and other industries. In the steam generation and superheating links, it quickly generates high-pressure steam with qualified parameters through efficient heat transfer, providing stable thermal support for processes such as steel rolling heating, chemical reactions and oil refining, and improving production efficiency.

- Waste Heat Recovery Boiler Field: As a core heat exchange component in sintering waste heat boilers of iron and steel plants and exhaust gas waste heat boilers of chemical plants, the internal thread structure can efficiently recover high-temperature waste heat (300℃-800℃) and quickly convert the waste heat into high-pressure steam, reducing energy waste and helping enterprises achieve the goal of “energy conservation and carbon reduction”.

- Special High-Pressure Boiler Field: Adapted to special high-pressure boilers such as waste incineration power generation boilers and biomass energy boilers. The internal thread structure can cope with the working conditions of complex medium components (including corrosive gases and ash) in such boilers. Through its anti-scaling and anti-corrosion performance, it avoids tube blockage and damage, and ensures the long-term stable operation of special boilers.

Adequate Stock

The company prepares more than 50,000 tons of special steel pipes all year round. Its material has SA106B, 20G, Q345, 12CR1MoVG, 15 CrMoG, 1Cr5Mo, 1Cr9Mo, 10CrMo910, A335P5/P9/P11/P12/P22/P91/P92, WB36 and all kinds of Austenitic stainless steel.

Application

Purpose of steel pipe:

1. Mechanical industry pipe. Such as aviation structure tube (round tube, oval tube, flat tube), automobile axle tube, axle tube, automobile tractor structure tube, tractor oil cooler tube, agricultural machinery with square tube and rectangular tube, transformer tube and bearing tube.

2. Pipe for petroleum geological drilling. Such as: oil drilling pipe, oil drill pipe (kelly and hexagonal drill pipe), drill, oil tubing, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drill, press collar and pin joint, etc.)

3. Tubes for chemical industry. Such as: petroleum cracking pipe, chemical equipment heat exchanger and pipe pipe, rust resistant acid pipe, chemical fertilizer with high pressure pipe and transport medium pipe.

4. Pipes for pipes. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and natural gas trunk pipe. Agricultural irrigation faucet with pipe and spray irrigation pipe

5. Pipe for thermal equipment. Such as the general boiler with boiling water pipe, superheated steam pipe, locomotive boiler with heat pipe, smoke pipe, small smoke pipe, arch brick pipe and high temperature and high pressure boiler tube 6. Tubes for other departments. Such as: container tube (high-pressure gas cylinder tube and general container tube), instrument tube, hand watch case with tube, syringe needle and medical instruments with tube, etc.

Package & Shipping

Package: Standard export package,wooden cases,wooden pallet,carton,etc

Loading Port: Tianjin port,Shanghai port,Qingdao port,Ningbo port, etc

MOQ: 1000KGS. for special size, the MOQ will be confirmed

Price Term: EX-WORK, FOB, CIF, CFR, CNF, DDP, etc

Delivery Time: ACCORDING TO THE ORDER”S QUANTITY.

FAQ

Q:How could I place a order?:

A:You can contact us by email about your order details,or place a order on line.

Q:Are the products in stock?

A:Yes.Most of our products are in stock.It can be prompt delivery.

Q:Could I customize?

A:Yes.It can be customized as per your request.

Q:Could you provide the samples?

A:No problems.Samples can be provided with samples charge and courier fee by the buyer’s side.

Q:What about the quality?

A:According to the standard for production.And we also accept the third-party inspection and quarantine.

Recently Viewed Products