ASTM A210 A-1 ASME SA210 A-1 Carbon Steel Tube Thermal Conductivity for Heat Exchanger Systems

OEM/ODM Custom Pipe Fittings

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

Lead Time:

| Quantity (pieces) | 1 – 100 | 101 – 1000 | > 1000 |

| Lead time (days) | 15 | 20 | To be negotiated |

Customized packaging(Min. order 10 pieces)

Graphic customization(Min. order 10 pieces

For actual requirements, please contact customer service.

Description

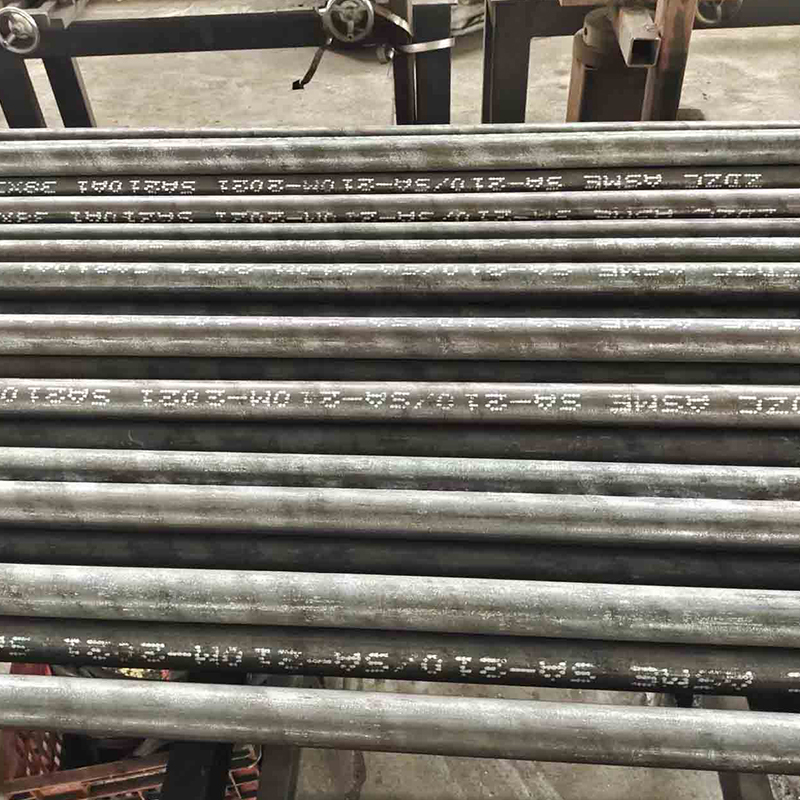

ASME SA210 A-1/ASTM A210 A-1

Chemical Composition

| Grade | % | C | Si | Mn | P | S |

|---|---|---|---|---|---|---|

| SA210 A-1 | Min | |||||

| Max | 0.27 | 0.1 | 0.9 | 0.035 | 0.04 |

Physical Properties

| Property | Density | Melting Point | State | Tensile strength | Yield strength | Elongation rate | Hardness | Recommended operating temperature |

|---|---|---|---|---|---|---|---|---|

| G/CM³ | °C | / | MPa | MPa | % | HRB/HB | °C | |

| / | / | Annealing | ≥415 | ≥255 | ≥30 | ≤79 HRB ≤143 HB | 450~650 |

Product Characteristics

SEAMLESS MEDIUM-CARBON STEEL BOILER AND SUPERHEATER TUBES

It is a high-performance steel pipe for boilers and superheaters, featuring pressure resistance, corrosion resistance and high strength.

Scope of Application

It is mainly used in boilers and superheaters, which can effectively ensure the safety and stability of high-pressure boilers and improve production efficiency and quality.

It is used in high-temperature and high-pressure environments such as gas turbines, nuclear reactors, and chemical equipment.

- Superior Pressure Resistance: Adopting seamless rolling technology, the tube wall features uniform thickness and dense structure, capable of withstanding long-term high pressure of over 9.8MPa (up to 30MPa for extreme working conditions). The compressive strength of the tube body is more than 50% higher than that of ordinary steel tubes, which can stably cope with pressure fluctuations during boiler operation and eliminate the risk of tube deformation or leakage caused by pressure overload.

- Precise Dimensional Control: Through precision sizing technology, the pipe diameter tolerance is controlled within ±0.1mm, the wall thickness deviation is less than 5%, and the tube straightness reaches ≤1mm per meter. This ensures precise connection with boiler system accessories, reduces installation gaps, lowers medium flow resistance, and guarantees thermal cycle efficiency.

- Excellent Thermal Stability: The tube body undergoes high-temperature normalizing + tempering treatment. Under long-term working temperatures of 450-650℃, the thermal expansion coefficient remains stable within 11×10⁻⁶/℃, avoiding thermal stress damage caused by sudden temperature changes and ensuring the tube maintains structural stability under boiler operating conditions with frequent start-ups and shutdowns.

- Efficient Heat Conduction: By optimizing the metallographic structure of the tube, the thermal conductivity reaches over 45W/(m·K), enabling rapid transfer of heat energy inside the boiler, reducing heat loss, and helping to increase boiler thermal efficiency by 8%-12%, which aligns with the needs of industrial production for energy conservation and consumption reduction.

II. Core Competitiveness, Building Differentiated Advantages in the Industry

- Full-Working-Condition Adaptability: Customization of tube length (3m-18m) and diameter (25mm-219mm) is supported according to industrial boiler types (power station boilers, industrial steam boilers, waste heat boilers, etc.). It is compatible with boiler systems using different heat sources such as fuel oil, natural gas, and coal, eliminating the need for structural modification of existing boilers and reducing equipment upgrade costs for enterprises.

- Strict Quality Control: Each tube undergoes three rounds of quality inspection: non-destructive testing (UT/MT inspection), hydrostatic testing (1.5 times the rated pressure test), and chemical composition analysis, achieving a 100% qualification rate. Complete quality traceability reports are provided, complying with domestic and international high-pressure boiler tube standards such as GB 5310 and ASME SA-210, preventing unqualified products from entering the market.

- Low Maintenance Cost Advantage: The tube exhibits excellent anti-scaling and anti-corrosion performance, enabling 3-5 years of maintenance-free operation under normal working conditions—more than twice the maintenance cycle of ordinary boiler tubes. This reduces boiler downtime caused by tube maintenance and improves the continuity of enterprise production.

III. Material Performance, Laying the Foundation for Safe Operation

- High-Quality Base Material Selection: Special boiler steel materials such as 20G, 15CrMoG, and 12Cr1MoVG are mainly used. Among them, 15CrMoG contains chromium and molybdenum alloying elements, with a high-temperature strength of over 450MPa, allowing long-term operation below 550℃; 12Cr1MoVG is added with vanadium, which improves oxidation resistance by 30% and can withstand high-temperature oxidation environments above 600℃, making it suitable for high-parameter boiler working conditions.

- Anti-Corrosion and Anti-Scaling: Chromium in the material forms a dense oxide film, which can resist corrosion from high-temperature water vapor and acidic media (such as residual chloride ions in boiler feedwater) inside the boiler. The smoothness of the tube inner wall reaches Ra≤0.8μm, reducing scale adhesion and lowering the risks of increased thermal resistance and tube corrosion caused by scaling.

- Strong Mechanical Properties: At room temperature, the tensile strength is ≥510MPa, the yield strength is ≥255MPa, and the elongation after fracture is ≥22%. It possesses excellent toughness and impact resistance, capable of withstanding vibrations and load impacts that may occur during boiler operation, thus preventing safety accidents such as tube breakage.

IV. Diverse Product Application Scenarios, Covering Core Areas of Industrial Thermal Energy

- Power Energy Field: Suitable for water walls, convection tube bundles, and superheater systems of large power station boilers. In thermal power plants and nuclear power plant auxiliary boilers, it undertakes the functions of high-temperature and high-pressure steam transportation and heat transfer, ensuring stable power generation of generator sets and meeting the power supply needs of the power grid.

- Heavy Industry Production Field: Used in industrial steam boilers in industries such as iron and steel, chemical engineering, and building materials. It provides high-pressure steam for processes such as steel rolling heating, chemical reactions, and cement calcination, ensuring stable temperature and pressure during production and improving the processing quality of industrial products.

- Waste Heat Recovery Field: As a core heat exchange component in industrial waste heat boilers (such as sintering waste heat boilers in iron and steel plants and exhaust gas waste heat boilers in chemical plants), it endures the high-temperature and high-pressure characteristics of waste heat media, efficiently recovers industrial waste heat and converts it into usable steam, helping enterprises achieve energy recycling.

- Centralized Heating Field: Adapted to high-temperature and high-pressure boilers in urban centralized heating systems, it transports high-pressure steam of 1.6-2.5MPa, ensuring minimal pressure and temperature loss during long-distance steam transportation and meeting the centralized heating and production steam needs of industrial parks and large residential areas.

Adequate Stock

The company prepares more than 50,000 tons of special steel pipes all year round. Its material has SA106B, 20G, Q345, 12CR1MoVG, 15 CrMoG, 1Cr5Mo, 1Cr9Mo, 10CrMo910, A335P5/P9/P11/P12/P22/P91/P92, WB36 and all kinds of Austenitic stainless steel.

Application

Purpose of steel pipe:

1. Mechanical industry pipe. Such as aviation structure tube (round tube, oval tube, flat tube), automobile axle tube, axle tube, automobile tractor structure tube, tractor oil cooler tube, agricultural machinery with square tube and rectangular tube, transformer tube and bearing tube.

2. Pipe for petroleum geological drilling. Such as: oil drilling pipe, oil drill pipe (kelly and hexagonal drill pipe), drill, oil tubing, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drill, press collar and pin joint, etc.)

3. Tubes for chemical industry. Such as: petroleum cracking pipe, chemical equipment heat exchanger and pipe pipe, rust resistant acid pipe, chemical fertilizer with high pressure pipe and transport medium pipe.

4. Pipes for pipes. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and natural gas trunk pipe. Agricultural irrigation faucet with pipe and spray irrigation pipe

5. Pipe for thermal equipment. Such as the general boiler with boiling water pipe, superheated steam pipe, locomotive boiler with heat pipe, smoke pipe, small smoke pipe, arch brick pipe and high temperature and high pressure boiler tube 6. Tubes for other departments. Such as: container tube (high-pressure gas cylinder tube and general container tube), instrument tube, hand watch case with tube, syringe needle and medical instruments with tube, etc.

Package & Shipping

Package: Standard export package,wooden cases,wooden pallet,carton,etc

Loading Port: Tianjin port,Shanghai port,Qingdao port,Ningbo port, etc

MOQ: 1000KGS. for special size, the MOQ will be confirmed

Price Term: EX-WORK, FOB, CIF, CFR, CNF, DDP, etc

Delivery Time: ACCORDING TO THE ORDER”S QUANTITY.

FAQ

Q:How could I place a order?:

A:You can contact us by email about your order details,or place a order on line.

Q:Are the products in stock?

A:Yes.Most of our products are in stock.It can be prompt delivery.

Q:Could I customize?

A:Yes.It can be customized as per your request.

Q:Could you provide the samples?

A:No problems.Samples can be provided with samples charge and courier fee by the buyer’s side.

Q:What about the quality?

A:According to the standard for production.And we also accept the third-party inspection and quarantine.

Recently Viewed Products